Vicon FixBale 500

Presse à balles rondes | Presse à chambre fixe

Presse à chambre fixe haute performance

Presse à chambre fixe à rouleaux PowerMax avec un diamètre de balle de 1,25 m

cc

- 2.3m extra wide pick-up with small diameter

- ChopFeed 15 knife pre-chopping system and PowerFeed rotor

- Large intake rotor for excellent cut quality

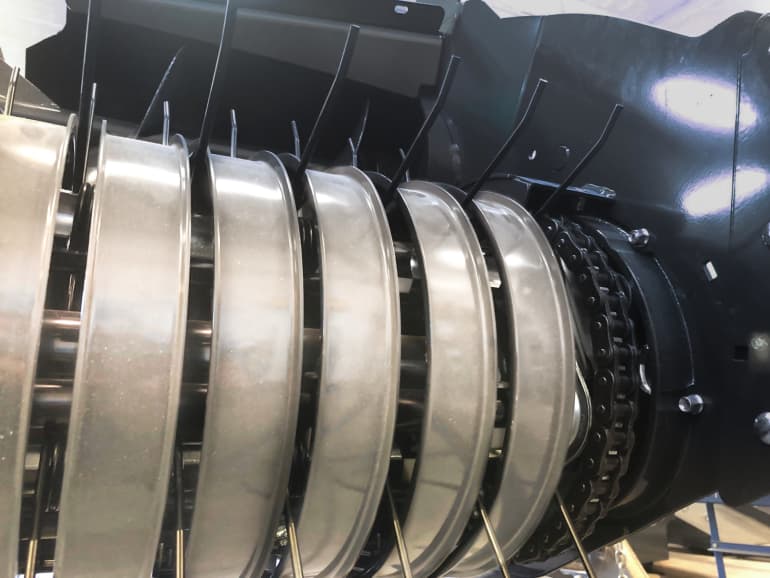

- PowerMax bale chamber with 18 ribbed profile rollers

- Patented PowerBind net system

- Intuitive control with the Focus 3 & ISOBUS terminal

Description

La FixBale 500 Vicon est la presse spécialisée pour l'enrubannage intensif. La chambre de pressage est formée de 18 rouleaux robustes et nervurés qui assurent une densité maximale et une excellente rotation des balles dans toutes les conditions. Dans le même temps, la puissance requise est réduite au minimum pour un fonctionnement optimal.

cc

- Le pick-up extra-large de 2,30 m à profil bas avec rouleau tasse andain assure un ratissage propre et une vitesse d'alimentation élevée.

- Le système SuperCut à 15 couteaux avec une longueur de coupe de 70 mm offre de hautes performances d'alimentation dans toutes les cultures.

- Système de fond escamotable monté sur parallélogramme avec un profil optimisé pour un flux de récolte plus régulier et un grand dégagement.

- Système de liage PowerBind breveté pour un liage par filet rapide et fiable.

- Chambre PowerMax à 18 rouleaux robustes conçue pour le fourrage humide et permettant d’obtenir des balles de haute densité et bien formées.

- Contrôle simple et intuitif avec le terminal Focus 3 ou la solution ISOBUS en option.

Caractéristiques

Caractéristiques

Extra-wide 2.3m pick-up, designated ‘XL+’ incorporates an extensive series of upgrades:

- Equipped with five tine bars with 32 tines per bar

- Each tine bar is supported by four ball bearings along its length

- Twin easy-access cam tracks located at both ends of the pick-up

- Large diameter roller crop press for increased intake speeds

- Innovative inboard driveline design for reduced transport width

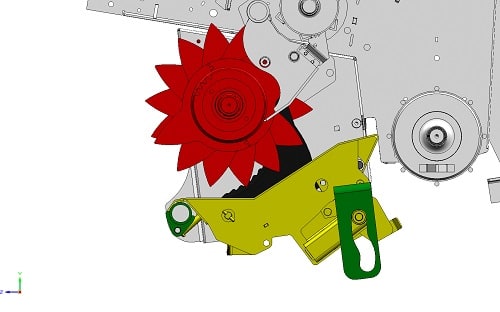

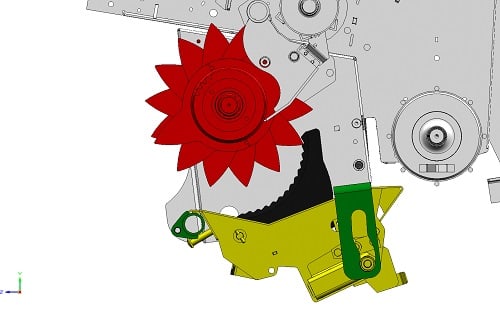

ChopFeed 15 Chopping system

ChopFeed 15 knife pre-chopping system provides higher efficiency and improved crop flow into the baler. Special profiled knives have been developed with a consistent chop length and low power requirement. With a chop length of 70mm, it is the ideal solution for producing tight, dense bales, which result in improved fermentation, with the further benefit of easier feeding out of bales and less wastage.

Individual Knife Protection

On the ChopFeed 15, each knife is individually spring-protected against foreign obstacles, giving it a higher level of protection than systems that protect only the complete knife bank.

New PowerFeed Rotor Intake

The new PowerFeed rotor intake system can achieve truly impressive intake capacity, efficiently handling all crop types, whatever the conditions. The massive intake rotor diameter provides the capacity to cope with the most challenging harvest conditions.

The SuperCut 15 intake system is equipped with the super effective Vicon Parallelogram drop floor system, which brings faster and easier clearing of blockages. The system not only lowers the rear edge of the drop floor as per traditional systems but also lowers the front section of the floor, where a blockage is more likely to occur.

FixBale 500 is equipped with the patented front mounted PowerBind net system. PowerBind eliminates troublesome feed rollers and has market-leading cycle time.

The net is continuously retained in the PowerBind injection arm. When the bale is 90% complete the arm moves forward ready for the net injection.

When the bale is 100% complete net is fed directly onto the bale in a flat movement angle keeping the net tight at all times, providing accurate and extremely reliable net injection. PowerBind gives you the confidence of doing a professional job, without any influence from wind or crop build-up.

Low Net Loading Height

PowerBind offers a very low loading height for maximum convenience and time-saving. To replace the empty roll just swing out the shaft and slide on a new roll.

The Vicon FixBale 500 is the specialist baler for heavy silage conditions. The PowerMax bale chamber incorporates 18 heavy-duty rollers arranged in a perfect circle for maximum bale rotation capability in all conditions. This is the ideal solution for producing well-shaped and dense bales. Production of consistent, high-density bales in both wet and dry material is assured. Two rollers in the lower section of the main bale chamber spread the load, reducing stress and increasing the working lifetime.

Adaptable Bale Density

For ultimate flexibility and ease of operation the bale density is hydraulically controlled and continuously monitored electronically. Density level can be precisely tailored from the comfort of the tractor cab according to prevailing crop conditions.

Techno-Pack has been developed to offer professional farmers and contractors the optimal solution in terms of crop harvesting management. The moisture level of the crop entering the bale chamber during the baling process is continuously measured and displayed on the baler terminal. Sensor plates are mounted in the lower part of the bale chamber, from which the system calculates the percentage of moisture inside the bale. The system is able to detect moisture levels up to 50% allowing the driver to decide at any time if crops such as hay or straw are fit for baling - your assurance of always preserving the best possible forage quality.

TIM (Tractor Implement Management)

TIM is a cross-product and cross-manufacturer ISOBUS solution for the agricultural machinery industry whereby the implement is able to control certain tractor functions. It enables two-way communication between tractors and implements, allowing both machines to work in perfect harmony. As well as increasing efficiency, the possibility of human error due to fatigue is also greatly reduced. TIM technology has the advantage of significantly increasing driver comfort by automatically performing many of the repetitive actions of the baling process.

The cost aspect is another factor to bear in mind. Highly efficient use of TIM-equipped baler results in lower costs for parts that wear out.

- TIM system as optional equipment

- TIM takes most of the work off the operator's hands when baling

- Significant increase in comfort for the operator, as endless work steps are saved

- Reduced operator fatigue and faster completion of work while maintaining high bale quality

- High user-friendliness of the TIM system, which even regularly changing operators can quickly master

Focus 3 Control

Vicon FixBale 500 is standard equipped with the Focus 3 terminal. All important settings are made from the comfort of the tractor seat, allowing for movement adjustment and a comfortable working environment.

Focus 3 is designed for easy operation with the following functions controlled from the terminal:

- Bale density adjustment

- Net quantity adjustment

- Tying information during the binding cycle

- Selection of manual or automatic binding

- Five daily bale counters & total bale counter

- Selection of knives, drop floor or pickup raise/lower function

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentation| FixBale500 PF | FixBale 500 CF15 | ||

|---|---|---|---|

| Type de chambre : | PowerMax | PowerMax | |

| Nbr de rouleaux : | 18 | 18 | |

| Dimensions des balles (m) : | 1.23 x 1.25 | 1.23 x 1.25 | |

| Largeur du Pick-up (m) : | 2,3 | 2,3 | |

| Nbr de barres/dents Pick-up : | 5 / 170 | 5 / 170 | |

| Tasse andain : | A rouleau | A rouleau | |

| Ameneur : | Rotor PowerFeed | Rotor ChopFeed-15 | |

| Longeur de coupe théorique (mm) | - | 70 | |

| DropFloor : | Sur parallélogramme (STD) | Sur parallélogramme (STD) | |

| Liage : | Filet / Filet & Film | Filet / Filet & Film | |

| Stockage filet (nbr) | 1+2 | 1+2 | |

| Hydraulique | 1 SE + 1 DE | 1 SE + 1 DE | |

| Largeur / Longueur / Hauteur (m) : | 2,52 à 2,76 / 4,15 / 2,30 | 2,52 à 2,76 / 4,15 / 2,30 | |

| Poids (kg) : | 3 400 | 3 600 |

Caractéristiques techniques

Caractéristiques techniques

Télécharger la documentationModel |

Bale Diameter |

Intake System |

Binding |

FixBale 500 CF15 |

1.23 x 1.22m |

ChopFeed-15 |

Net |

FixBale 500 PF |

1.23 x1.22m |

PowerFeed |

Net |